2019 Husqvarna Vitpilen 701 June 26, 2019 – Posted in: Bikes2

The 2019 Husqvarna Vitpilen 701 – Our first non-client build. New bike, fresh out of the crate. We’ve always been suckers for the old mx-bikes and the looks of them, so the brand Husqvarna was no stranger for us.

The 701 is, completely stock, quite a stunning bike. You can see at first glance that a team of new-wave designers – Kiska from Austria – had their way with it. We chose the 701 because we felt it was the right time to do so. The 701 is one of the first bikes where the design is so much more than functional. The details are crazy good – not only the visual ones, but also the tech parts. All the way up to the brazed-on tabs for the tie-wraps.

We really liked working on the Bonneville’s and lets be honest, newer bikes are so much nicer to wrench on. No rusted bolts, thought-through and no PO bodgejobs. The complete budget can be spend on visual and performance whilst on older builds half will go into making it acually run proper. As the 2019 Vitpilen was only out a couple days after we could get it, – we got a crazy good deal on it thru Mulders Motoren (who also managed to wedge the spoked wheels into the deal) located in Veendam, NL – we like the bike stock, it was 3 months before the 2019 BikeShed show in London and because it’s a crazycool opportunity to grow and expand our brand, it was the perfect thing to do.

We got the bike and the same evening we tore it apart. With every build it’s a scary point-of-no-return but with this one it was even wilder as the bike couldn’t even run due to the transport lock still on it.

Now, i want to give some massive props to the designers over at Kiska and Husqvarna, cause this machine is an absolute joy to work on for customizers. It looks like it was designed solely to get it customized. Everything is SO WELL thought through! The whole subframe is held on with 4 bolts which is ideal because well.. you only have to remove 4 bolts. But, and way more important.. The main frame stays intact giving massive design options in almost all counties. 85% of the wiring is in the main frame aswell – our subframe only houses battery, starter relais and some tuning/canbus plugs.

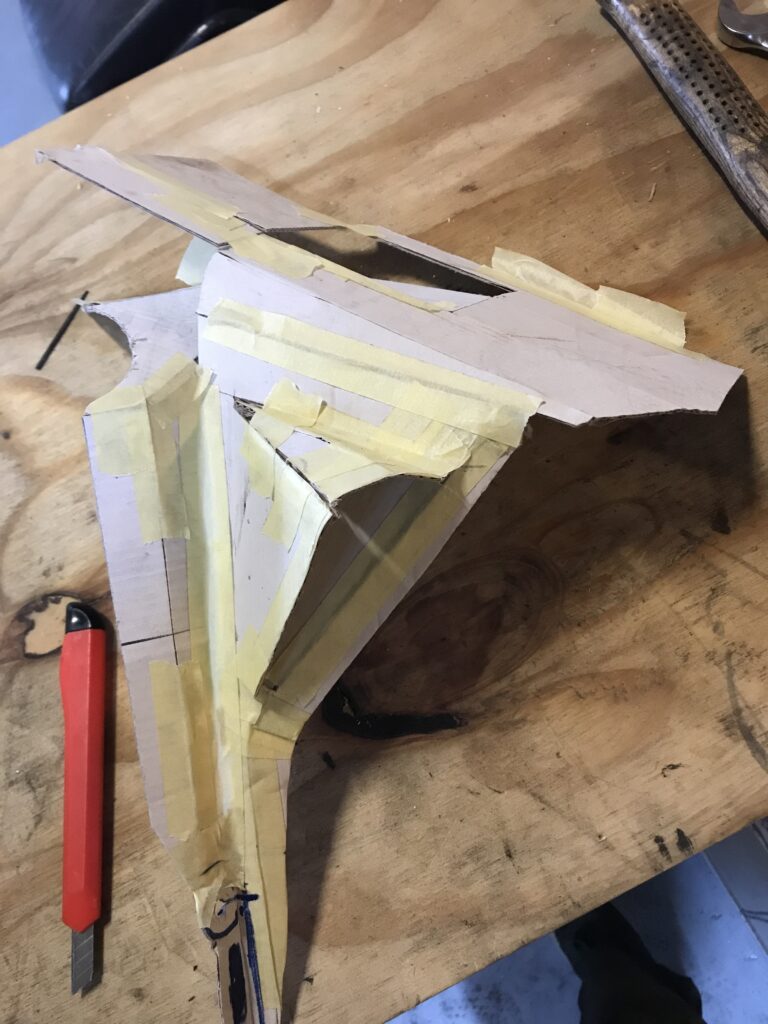

The Subframe, as good is it is, had to go. It’s lumpy and gives the bike weight it does not need. It also gives the bike a very distinct look and not much design options. Tubed frame look nicer, cleaner with the main frame and lighter so that was the first part that we fabricated. We used the stock subframe to make a jig for the new one and went to work.

Next part we changed was the swingarm. The milled box-type didn’t fit the looks we had in mind, we wanted the swingarm to be tubes like the frame.

Again, a jig was buid with the original swingarm as mold, with the only big difference being the new one is 30 mm shorter. The stock one is so freaking long, and 30mm might not seem like much, it is. Visually and Wheelieally. (Is that even a word?)

The tank design is a personal want. I had this idea in my head for so long and finally had the opportunity to do it. Massive undertaking, took 2 weeks to design, cut, weld and pressuretest but it came out pretty good. The stock fuelpump, fuellevel meter and cap were re-used. We like to mix the stock stuff with the new, gives it a prototype vibe if done right.

Forks are kept stock, as they’re good. USD, WP suspension and Brembo radial. That’ll do. Front fender is custom, made out of 2 pieces of mild steel welded in the middle. Took a whole day designing, another one to cut and 2 more to weld and shave. We wanted a clean straight line along the subframe, tank and fender and although it’s hard to see on the pictures, the line is there.

Handlebars and risers are from Neken, because clip-ons suck balls on a 690cc single. The topclamp is made by Scheffers Engineering in Norway.

Throttle system is fly-by-wire on the Husqies but the big chuck of plastic on the handlebars is ugly. We relocated the system underneath the tank and made a cable-operated pulley system so a ‘normal’ throttle could be used. Motone buttons on the stock wiring and some Motogadget magic make it all work flawless.

Exhaust is completely custom, made out of 42mm 316 stainless with elbows because we wanted the hard corners in the exhaust without sacrificing performance. A full day of grinding the welds make it look like one piece.

As with all our builds, we don’t take off with a clear plan but like to see it evolve throughout the build. Massive learningcurve for us and we hope you like it as much as we do!

At this moment the bike is still for sale, email us for more information.

Visual Awesomeness by WinchesterCreatives.